● 位置/速度/转矩控制模式。

● 混合控制模式∶位置/速度、速度/转矩、位置/转矩控制模式。

● 指令来源选择∶内部/外部位置指令;内部/模拟量速度指令;内部/模拟量转矩指令。

● 模拟转矩限制/模拟速度限制。

● 多组电子齿轮比切换。

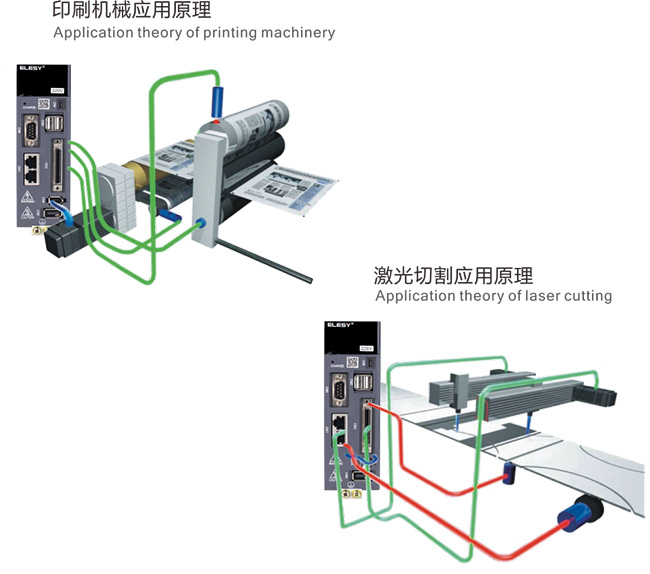

● 应用实例︰送料机、薄膜分切机、卷绕机、包装机械、印刷机械、绣花机机械、绕线机械、激光切割机械。

● Position / speed / torque control mode;

● Mixed control mode: position / speed, speed / torque, position /torque control mode;

● Command source selection: internal / external position command,internal / analog speed command; internal/analog torque command.

● Analog torque limit / analog speed limit

● Multiple sets of electronic gear ratios are switched.

● Examples of application: feeder, film splitter, coiler, packaging machinery,printing machinery, embroidery machinery, winding machine and lasercutting machinery.

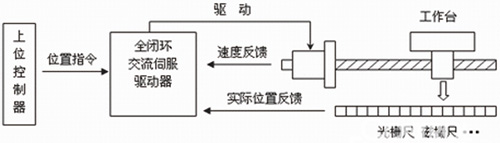

● 支持外部编码器、光栅尺(A、B、Z格式)等

● 降低机械打滑和传动背隙的影响,保证机械终端定位精度

● 应用实例︰数控机床、送料类型设备等

● To support external encoder and grating scale (A, B,Z format)

● To reduce the impact of mechanical slipping and transmission back clearance and ensure the positioning accuracy of mechanical terminals

● Examples of application: CNC machine tools, feeding machine, etc.

● 多组增益选择以及增益切换功能。

● 位置前馈、速度前馈功能,可显著减小追随误差。

● 负载惯量比设置,在线辨识功能,简化增益调整。

● 陷波器功能,消除机械共振引起的振动与异响。

● Multiple sets of gain selection and gain switching function

● Position feed forward and speed feed forward function can significantly reduce tracking error.

● Load inertia ratio setting, online identification function and simplified gain adjustment.

● The wave trap function eliminates vibration and abnormal noise caused by mechanical resonance.

● 凸轮曲线数据可达720点。

● 相邻两点之间由软件插补三次曲线,点数多寡不影响运行平滑性。

● 支持飞剪、追剪以及自定义曲线规划

● 可方便的使用ELESY Soft软件进行规划与设置。

● 驱动器内置飞剪、追剪宏指令,可直接对曲线进行调整与重新规划。

● The cam curve data can reach 720 points.

● The cubic curve is interpolated by software between two adjacent points,and the number of points does not affect the smoothness of the operation.

● To support flying shear, chasing shear and customize curve planning

● Easy to use ELESY Soft software to make planning and setting

● The driver has the macros for built-in flying shear and chasing shear to directly adjust and re-plan the curve.

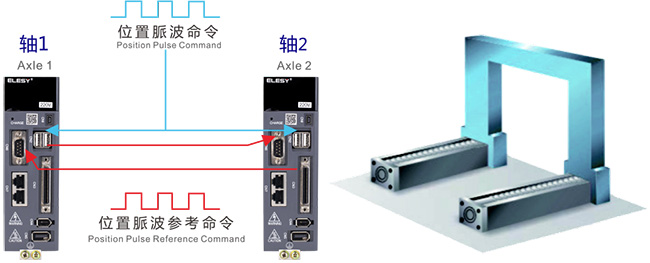

● 龙门式机械机构可以使用双轴驱动,驱动器自动进行位置同步。

● 当同步位置偏差超过设定值后,驱动器会发出报警并停止运行,上位机同时给两台驱动器发脉冲指令,

● 通过将两台驱动器位置反馈脉冲信号交叉连接,

● 实时调节电机运行速度,使两轴位置同步。

● The gantry-type mechanism can be driven by double shaft and the driver can synchronize its position automatically.

● When the deviation of synchronized position exceeds the set value, the driver will give an alarm and stop running.

● The servo system computer sends pulse commands to two drivers simultaneously.

● Via cross connection of position feedback pulse signals from two drivers, the motor running speed is adjusted in real time to synchronize the positions of two shafts.

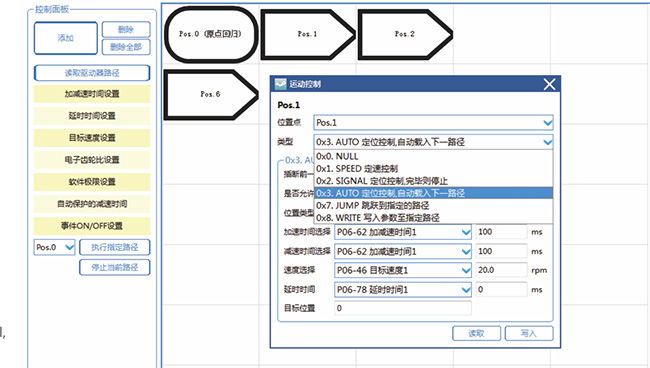

● 提供32段路径可供使用者灵活规划。

● 路径类型包括:原点回归、定速控制、定位控制、修改参数、跳转路径等。

● 位置控制支持:绝对定位、相对定位、增量定位、CAP抓取定位。

● 多段加减速时间、延时时间、目标速度可选。

● 位置控制采用PUU用户单位,方便使用。

● 多种触发方式:软件触发、CNTR信号触发、EV1/2/3/4事件触发(跳沿可选)。

● ELESY Soft软件采用图形化设置操作,设定简便。

● To provide a 32-segment path for the user to make the planning flexible.

● Route types include: zero return, constant speed control, positioning control,modification parameters, and jump path.

● Position control support: absolute positioning, relative positioning,incremental positioning, CAP capture positioning.

● Multi-stage acceleration /deceleration time, delay time and target speedare optional.

● It is convenient to use with the adoption of position control

● Multiple trigger modes: software trigger, CNTR signal trigger,EV1/2/3/4 event trigger (jump edge optional).

● The graphical setting operation is made via ELESY Soft software and easy for setup.

● 内置RS-485接口,支持MODBUS通讯协议。

● 支持MECHATROLINK-II/III总线通讯协议。

● 支持CANopen总线通讯协议,支持CiA-301、DSP-402子协议。

● 支持EtherCAT总线通讯,应用层采用IEC61800-7 CiA 402-CANopen运动控制子协议。

● 配合相应上位控制器,如CNC数控系统、PLC、控制器等,可实现多台伺服驱动器组网运行。

● With the built-in RS-485 interface, support MODBUS communication protocol.

● To support MECHATROLINK- II / III bus communication protocol.

● To support CANopen bus communication protocol, support CiA-301,DSP-402 sub-protocol.

● To support EtherCAT bus communication and IEC61800-7(CZA402)-CANopenmotion control sub-protocol is adopted for the application layer.

● With the corresponding servo system controller,such as CNC numerical

control system, PLC, controller, etc., multiple servo drivers can be networked.

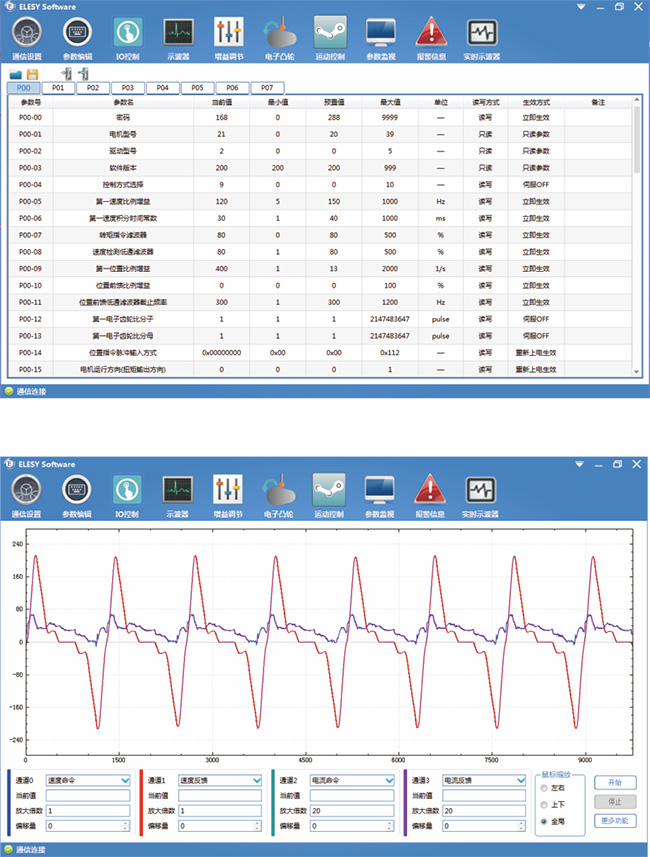

● 支持通过RS-485或USB与驱动器通讯,即插即用,连接简便。

● 参数编辑器允许用户实时查看修改伺服参数,并提供参数说明、设定范围等信息。支持导入、导出用户参数表,能方便的批量配置伺服驱动器。

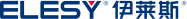

● 示波器支持4通道数据采集,刷新速度1kHz。

● 用户可以监测伺服运行波形,对波形数据可进行缩放、测量、导入、导出等操作。

● IO控制器可直接选择端子逻辑和功能,并实时查看端子状态。

● 运动控制与电子凸轮功能,采用图形化设置,

● 可以方便的对相关功能进行配置与调试。

● 此外还提供增益调节、参数监视、报警信息等功能。

● To support communications with the driver through RS-485 or USB;plug and play, easy to connect.

● The parameter editor allows the user to view the modified servo parametersin real time and provide and provide information such as parameter descriptionand setting range; import support and export the user parameter tables, whichcan conveniently configure servo drivers in batches.

● The oscilloscope supports 4-channel data acquisition with a refresh rate of 1 kHz,

● The user can monitor the servo running waveform, to scale, measure, import, andexport the waveform data.

● The IO controller can directly select terminal logic and the function to look at thestatus of the terminals in real time.

● Graphical settings is used for motion control and electronic cam function.

● Easy to configure and debug related functions.

● In addition, it also provides functions such as gain adjustment, parametermonitoring and alarm information.

● 驱动器可共直流母线,能量充分利用,设备更节能;

● 减小制动电阻数量及功率要求,降低配件成本。

● 应用案例∶印刷设备、纺织设备、收放卷设备等。

● The driver can share the DC bus and the energy is fully utilizedso that the device is more energy- efficient;

● To reduce the quantity of braking resistors,power requirementsand the cost of accessories.

● Cases of Application: printing equipment, textile equipmentand unwinder / rewinder

扫一扫

关注公众号